To produce quality at first time, every-time, multiple inspections are carried out depending on the production stage.

Both our raw and dyed fabrics undergo rigorous testing to ensure they meet the standards.

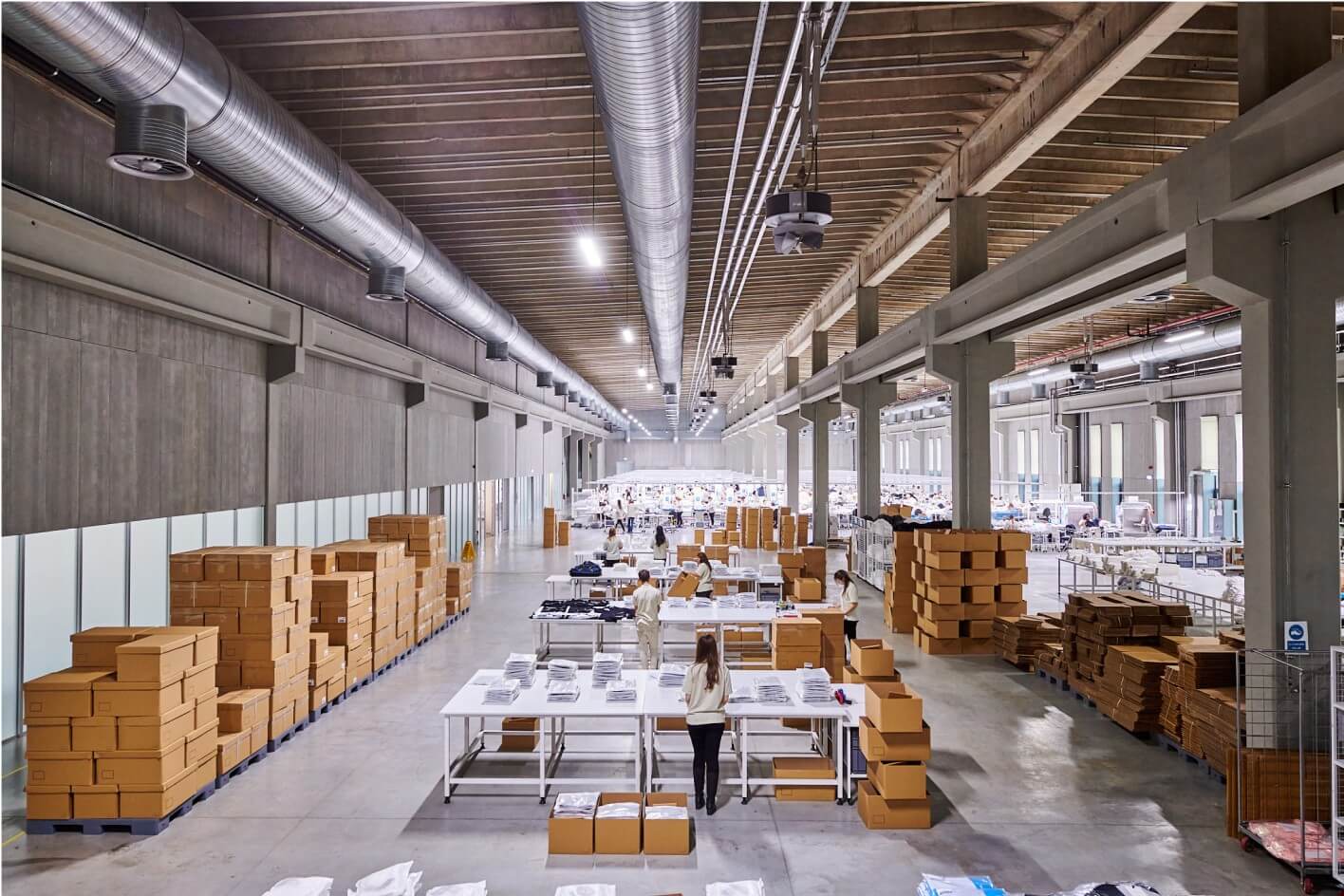

In addition to pre-packaging evaluations, AQL 1.5 or AQL 2.5 final inspections are made to monitor the quality.

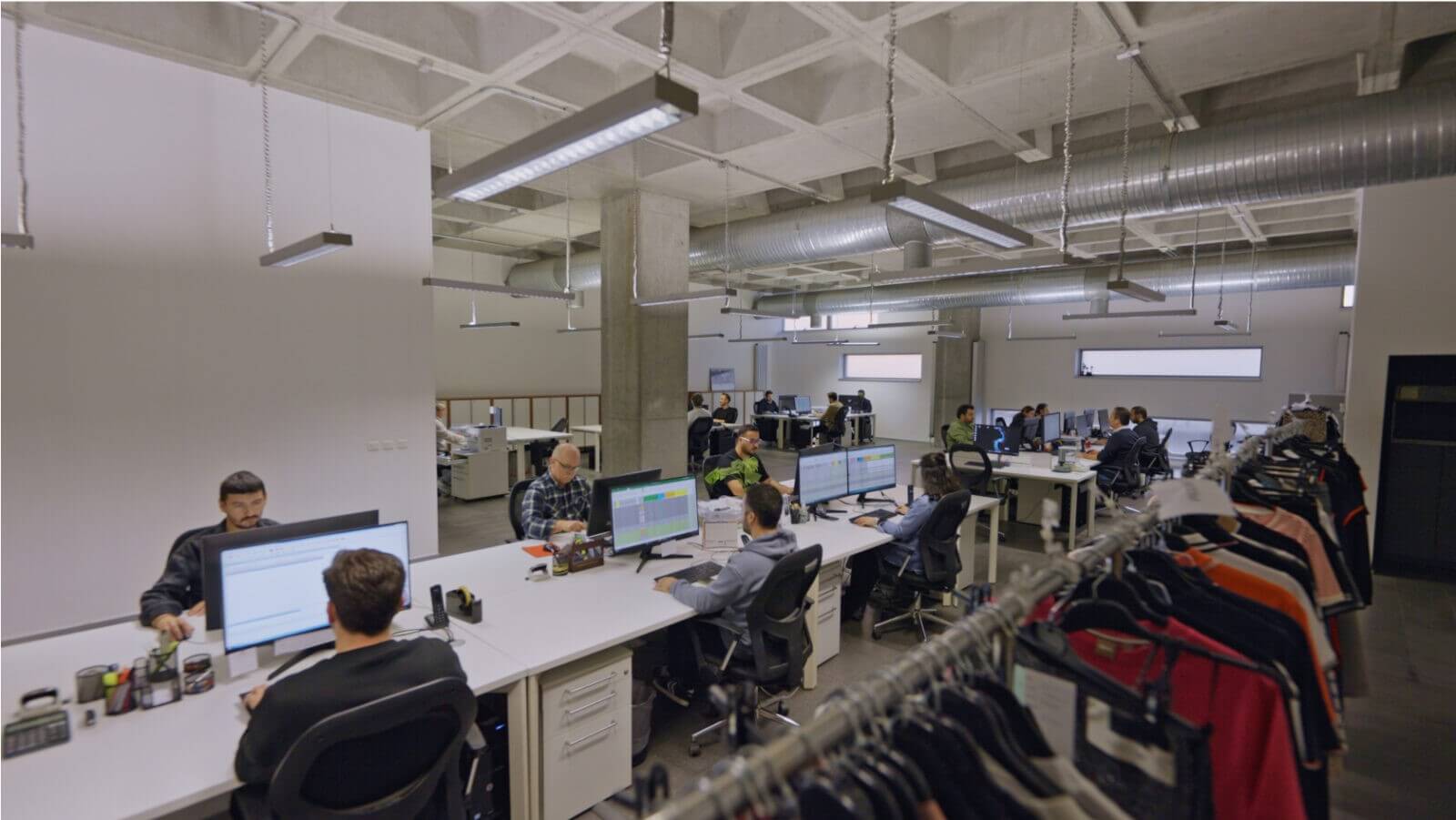

Method Time Measurement (MTM) is used to measure method and processes prior and during production.

Our factories are Global Organic Textile Standard (GOTS), Recycled Claim Standard (RCS), Organic 100 Content Standard (OCS), Global Recycled Standard (GRS) and Better Cotton Initiative (BCI) certificated. Additionally, we hold ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System) certificates.